USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

Mold flow analysis is also called MFA, which uses softw […]

Mold flow analysis is also called MFA, which uses software to create simulations of plastic flow. It can allow plastic parts manufacturers to enhance their mold designs and create better products through flow analysis of injection molds.

Through mold flow analysis, manufacturers can understand how the materials they use fill the mold cavity and find possible problems. Before the physical cutting starts, create a virtual version with the mold flow analysis software of the mold, which allows you to make changes and save production costs.

When to use Moldflow analysis?

Modern software programs can be very beneficial in the plastics manufacturing environment. Part designers have programs such as stress analysis tools that work with CAD models to highlight weak areas of a design.

Similarly, for the manufacturing side of the business, Moldflow is a program that is intended to analyze a plastic injection molded part in terms of its manufacturability. Here are some factors that help determine whether the MFA is necessary for the application:

1. Tolerance requirements – products with tighter tolerances can benefit from MFA before processing to ensure that you can meet mold design and material specifications.

2. Product geometry – A mold with a more complex shape may benefit from mold flow analysis because the flow is more difficult to predict than a simple shape.

3. Project scope – there is a cost associated with performing mold flow analysis. The scope of the project should be wide enough to justify the expenditure of money and manpower related to the Master of Arts.

The benefits of Moldflow analysis

A good mold flow analysis has many benefits. Although it is time-consuming, the cost is much lower than the cost of the day and night testing on the production injection molding machine. Here are some common benefits of using mold flow analysis include:

1. It can solve the wall thickness problem.

2. MFA allows you to fill the cavity of the mold with consistency.

3. You can spot errors in design geometry and avoid expensive tool errors. If you need to explain the design changes to the customer, it will also give you more support.

4. It can help you increase production capacity, improve quality and efficiency, and shorten time to market.

5. Mold flow analysis allows you to find visual defects such as air traps, weld lines, and dents and allows you to optimize gate locations.

6. The program can predict general molding parameters so that effective settings can be made during the test phase.

Key aspects of Moldflow analysis

Mold flow will assess many different parameters of the molding process to give both designers and manufacturing engineers a strong understanding of how well the real thing will go. Here we will look at a few key aspects of a Moldflow report and what value it adds to the process.

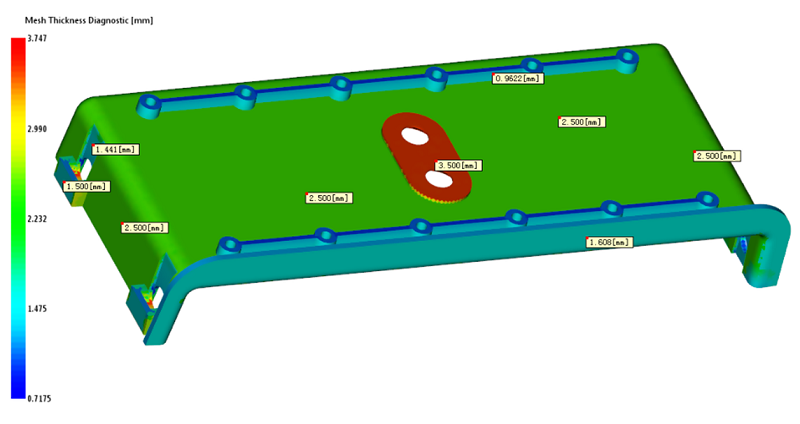

1. Part thickness

Although this is something that designers of plastic parts usually have to focus on, and also something that is usually discussed in a DFM document provided by the toolmaker, here Moldflow can analyze the thickness of your part and provide feedback on areas that may be too thick/thin.

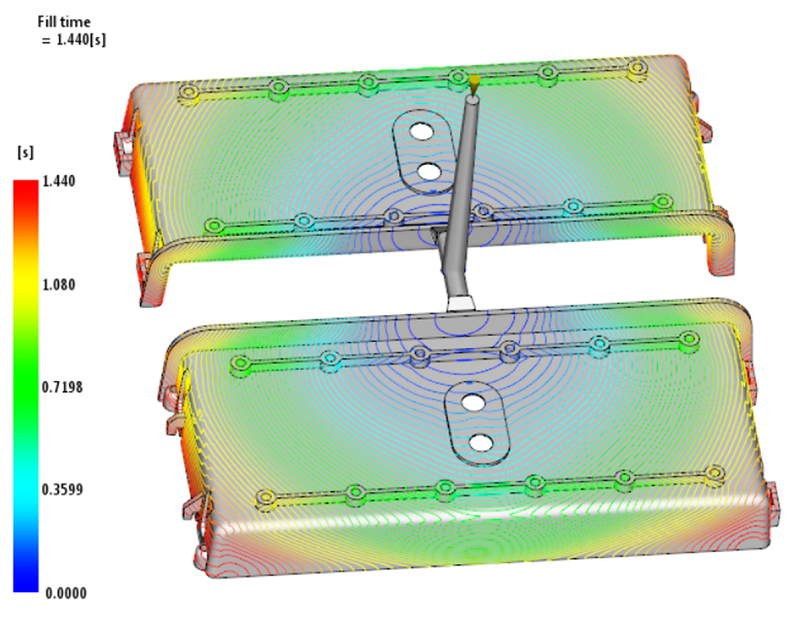

2. Filling the part tool cavity

How the part fills will have an effect on how the finished part comes out of the mold. Areas that fill too slowly may require excessively high injection speeds or pressures in order to avoid short shorts as the flow cools in the mold before it is full. High injection speeds can lead to shearing of the resin, and excessive pressure can limit the machine size the part can be made in, or possibly cause it to not run at all if the machine clamping force is limited in your production facility.

Moldflow allows early detection of slow filling areas which can then be mitigated with design to prevent these problems from ever occurring. Being able to assess how quickly the product will fill also allows the production engineers to estimate the cycle time of the part. Knowing in advance with more certainty allows product scheduling in the mold shop to be more efficient. Cost estimates for new products being introduced can also be more accurate as the estimated manufacture time can be confirmed per part.

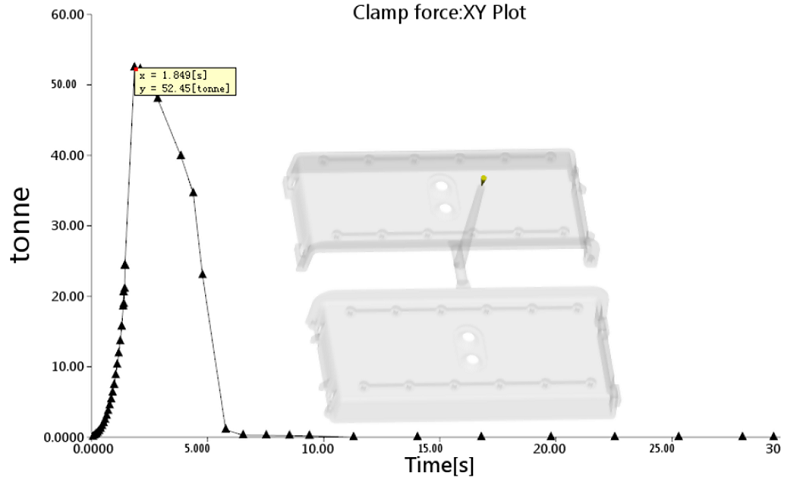

3. Pressure/Clamp force

Calculating the required pressures to fill the part, Moldflow analysis can highlight any unexpected pressure anomalies in a part and confirm to the business which machines they have will be viable to run the part in. This not only helps to resolve any unexpected pressure situations but also allows a molding facility to designate machines that the part can be run on for future production scheduling.

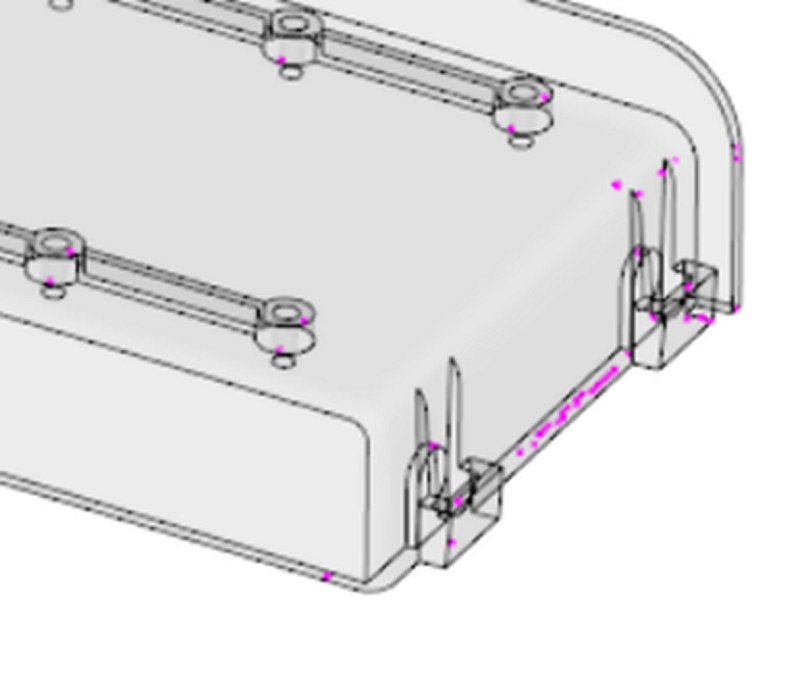

4. Air traps

A great advantage Moldflow offers are being able to visualize where air traps will occur. Trapped air that cannot escape can cause voids or gas in a part. Gassing occurs when the trapped air becomes compressed and combusts due to high temperatures. The result is a burn mark on the part which looks bad especially on lighter colors.

The picture on the right shows where Moldflow has highlighted potential air traps. This allows them to be dealt with early on, thus preventing gassing from ever occurring. The gas can be removed by adding inventing in the area that the pockets of air occur (quite often at the edges of a part where the melt flow reaches last).

Another way of dealing with air traps is to look at the gate location in order to direct the melt flow to a certain area, therefore allowing venting to be strategically placed.

5. Weld lines

Weld lines are a fact of life for molded parts, wherever there are holes placed. It is easy enough for experienced designers to predict roughly where they are going to occur, however, it is useful to know in more detail especially as holes are often used as structural features. Being able to visualize the results may guide design change if weld lines become apparently problematic.

The colored lines on the picture above show where Moldflow predicts the weld lines will be. This is normal for a part like this with many bosses and hole features.

6. Shrinkage

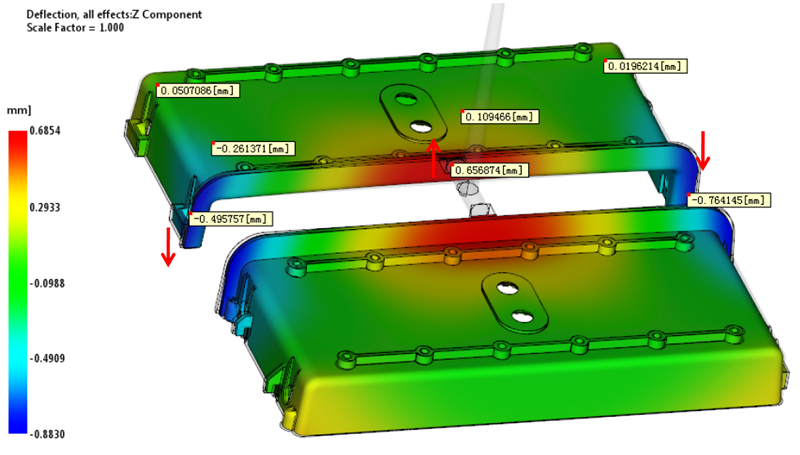

One of the most important factors in molding, and one that can make all the difference between a good and a bad part. Warp (caused by uneven shrinkage) is a cause of headache for designers and manufacturers alike. There is nothing worse than seeing your beautifully straight designs come to life as a twisted mess! Many factors go into the shrinkage and lots of methods for reducing this are available to the production engineer/molding tech. however, it’s good to get it right from the very beginning.

Moldflow can give extensive shrinkage analysis, giving reports on the shrinkage in all planes. This allows the designer to see where their part will most deform from the nominal, and give chance for any corrections to be made.

Shrinkage/warpage can be dealt with in numerous ways at the design phase, adding ribs, changing wall thicknesses, changing gate locations, etc are just some of the options available. If the problem is not discovered until trials, there is less that can be done to mitigate without costly redesign and tool modifications.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.