USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

The end product of an injection molding process depends […]

The end product of an injection molding process depends on a number of factors, both internal and external. Most of these factors are within the control of operators and for this reason, special care has to be exercised to ensure that everything works as intended.

The points of injection mould gating system affect the plastic products

1. Gate size

When it comes to the gate size, there has to be a balance struck between filling the mold to its exact capacity and keeping the smallest runner active to further improve the shearing. Striking this balance is easier said than done, and the smaller the gate, the smoother and nicer the appearance of the final product. However, they take a lot longer to fill, and this is a recipe for defects that can form due to cooling at different times and the use of varying pressures on either end of the product.

2. Gate location

The location of the gate plays a vital part in how the final product will come out looking. The best position of an injection molding gate would be a deep area of the cross-section area so that it can provide the best-molten material flow while cutting down the voids and sinking defects. At the same time, the gate should be supported by a piece of the mold in places where the distortion that can be caused by the pressure stress can alter the aesthetics of the final product.

3. Number of gates

Sometimes, the number of gates has to be increased to get rid of some defects that are common in the other factors above. In situations that require large molding parts, then using a single gate simply won’t cut it. By using multiple gates, you will be able to control how the molten material is fed into the crates, and this control will help create better and more refined products in the long run. The only drawback to increasing the number of gates is an increase in the production time, but what you get in return in terms of quality is worth it.

Common defects caused by gate system design

Injection molding is without faults, after all, anything that makes use of heat will always develop some issues due to the overriding external conditions. Some of the most common defects that can arise due to a faulty gate design include the following.

1. Flow marks

These are the visible lines you see on the surface of a plastic product that is different from the uniform texture of the surrounding areas. Sometimes they appear as wavy lines and at times as ring-shaped bands. They rarely impact the structural integrity of the object, but they do affect the appearance negatively.

Flow lines are caused when there are huge variations in the cooling speed as the molten material meters the crate and flow to different areas. The varying thickness of the mold walls could also lead to this defect, and it can be rectified by using gates that have uniform wall thickness as well as increasing the diameter of the injection nozzle.

2. Burn marks

These are discoloration marks that usually appear as rusted or black edges on some parts of the finished plastic product. They are an aesthetic defect that rarely touches on the functionality of the product unless the damage extends to the point of causing degradation. The cause of this defect is air being trapped during the injection molding due to deformed gates that are not stable. Switching out the gates and enlarging them and the vents would help get rid of this deformity once and for all.

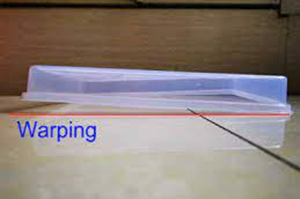

3. Warping

This is the most common deformation that afflicts plastic molded materials, and it is caused when the different parts of the just-finished item cool unevenly. This uneven shrinkage exerts pressure on the entire item, and the more it cools, the bigger the warp until it solidifies permanently into place. This defect can affect the functioning of the product and should be rectified immediately once it shows up to avoid the same happening to other products.

4. Air pockets

This is a defect that is prevalent in clear plastic products and manifests itself in the form of little air pockets trapped deep inside the finished item. On top of giving the item a bad look, these pockets can undermine the structural integrity of the product if they are pronounced enough. The biggest cause of this defect is the lack of adequate molding pressure that is necessary to expel air from the mold before the gate is closed. Rapid cooling is also another possible cause. To counter it, simply increase the pressure of the molding process and choose materials with lower viscosity.

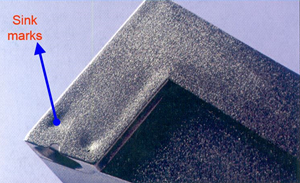

5. Sink marks

These are small depressions and dents that appear on flat surfaces in a way that is inconsistent with the rest of the molded item. This is usually caused when parts of the item cool very slowly resulting in shrinkage that pulls the outer parts inwards before the closing process is complete. These depressions can be so big to the point where they can affect how the entire product functions. The easiest way to counter this defect is by increasing the holding pressure and time and increasing cooling time to reduce the shrinkage.

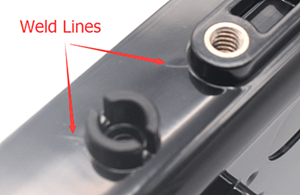

6. Weld lines

This is a line that appears at the point where two different parts of the same item are welded together. It is hair-like and is caused by weak materials trying to bond with each other. Besides affecting the aesthetic nature of the product, it also affects the strength of the area that has the weld lines. The most common cause of this is when two different parts collide and become insufficiently solidified. The common remedy for this would be to increase the temperature of the material and the speed and pressure of the injection.

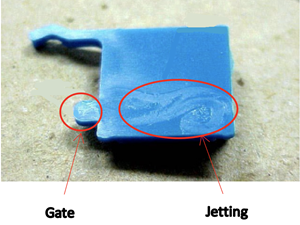

7. Jetting

This is a deformation that appears when a jet of molten material is injected into the cavity and starts solidifying before the mold is filled up. This creates a squiggly line on the surface of the material in a distinct pattern. This defect can lead to part weakness, and most objects that feature this defect usually end up being written off. It can be rectified by reducing the injection pressure through the gate, increasing the temperatures of both the materials and the mold, and designing the injection gate in a way that allows the molten material to be injected across the mold instead of lengthwise.

How to improve gate design to get quality plastic products?

When you consider all the defects that are present due to bad gate designs, the need to find solutions becomes even more important. To fully get the best out of the injection molding gates, the following are some of the improvements you can carry out to ensure everything comes out just right.

1. The gate location should be placed on the parting surface to ensure easier CNC machining and maintenance.

2. Always design the runner to be even. Everything from the mold flow to the sectional size should be in perfect balance for the molding gate to function as it should.

3. The gating location should also be flanked with thick walls to ensure that the cavity can be filled completely during the injection process.

4. When injecting molten material, ensure that the mold flow doesn’t go in on the inserts. This could lead to,; getting the pressure of the mold flow being pushed too high, deforming the final product in the process.

5. Add venting when designing the gating system to ensure that the end of the mold flow gets a good venting which in turn ensures that the products being molded come out in the right shape with minimal defects.

6. The most important design tip you should always include in the gating system is the ease of removal. There should be a mechanism that allows for the safe removal of the gating without affecting the functionality and appearance of the molded parts.

Taizhou Saiweiyue Mould & Plastic Co., Ltd.

ADD: No.12, Jinchuan Road, Beicheng Street, Huangyan District, Taizhou City, Zhejiang Province, 318020, China

Mobile/WhatsApp: +86-15757668880

Tel/Fax: +86-0576-89888400

E-mail: [email protected]

[email protected]

Copyright © Taizhou Saiweiyue Mould & Plastic Co., Ltd. Rights Reserved. Plastic Injection Mould Manufacturers injection molding Suppliers