USING SCIENTIFIC MOULD-MAKING TECHNIQUE TO PROVIDE YOU WELL MOULD.

The core of making plastic reflector injection mold is […]

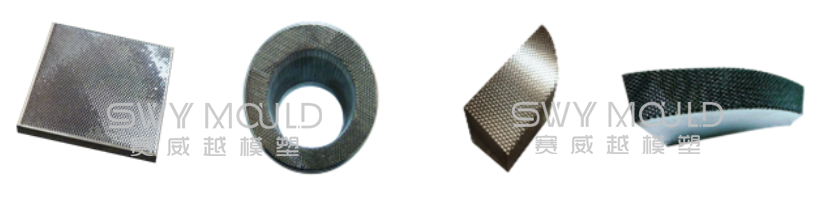

The core of making plastic reflector injection mold is the mold insert.

Knowledge about reflector mold insert

Reflectors are used in the rear lamps fixed to vehicles, bicycles, highway delineates, industrial sensors, and so on. Reflector molds require precision work and special technology and knowledge of optics, so it's a hard job for some mold companies.

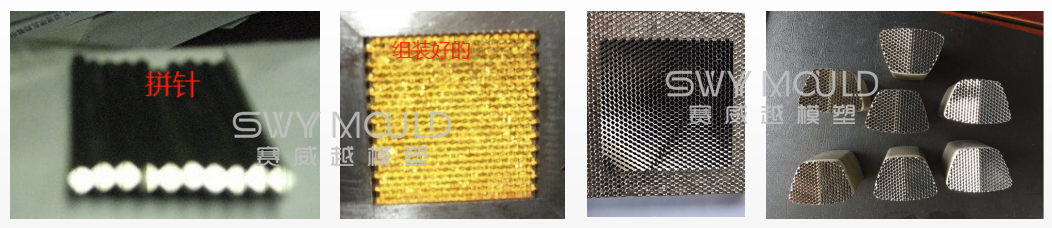

The core of a reflector mold is made of bound hexagonal pins whose heads are mirror-polished in a 3-D triple mirror. High precision is required for the angle of the finished surfaces. The core of the mold for the reflectors of 3-D curved surfaces like the rear lamps of vehicles is electroformed, formed from a pin-bound master.

The process of making reflector mold insert

1. Machining the needle---5 days

2. Assembling the template---5 days

3. Electroform---around 35 days

4. According to product wire cutting, then assembly---around 7 days

Viewing our storage of the plastic reflector injection mold insert

Taizhou Saiweiyue Mould & Plastic Co., Ltd.